CHEMICAL INJECTION SYSTEMS

CHEMICAL INJECTION SYSTEMS

EEServ also offers complete Chemical Injections Systems. This allows us to take your process chemical injection concepts to full implementation in one shop, under one roof.

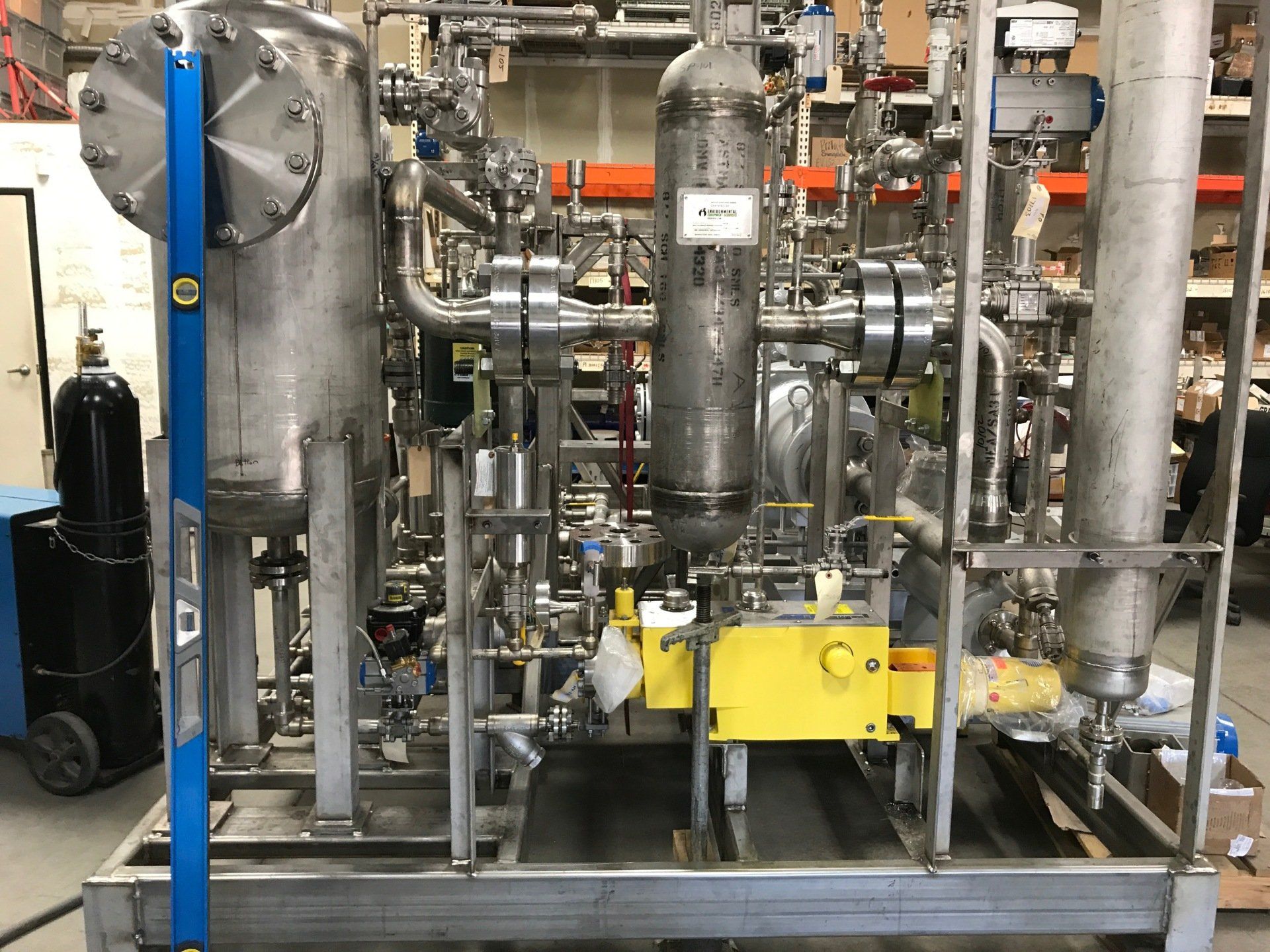

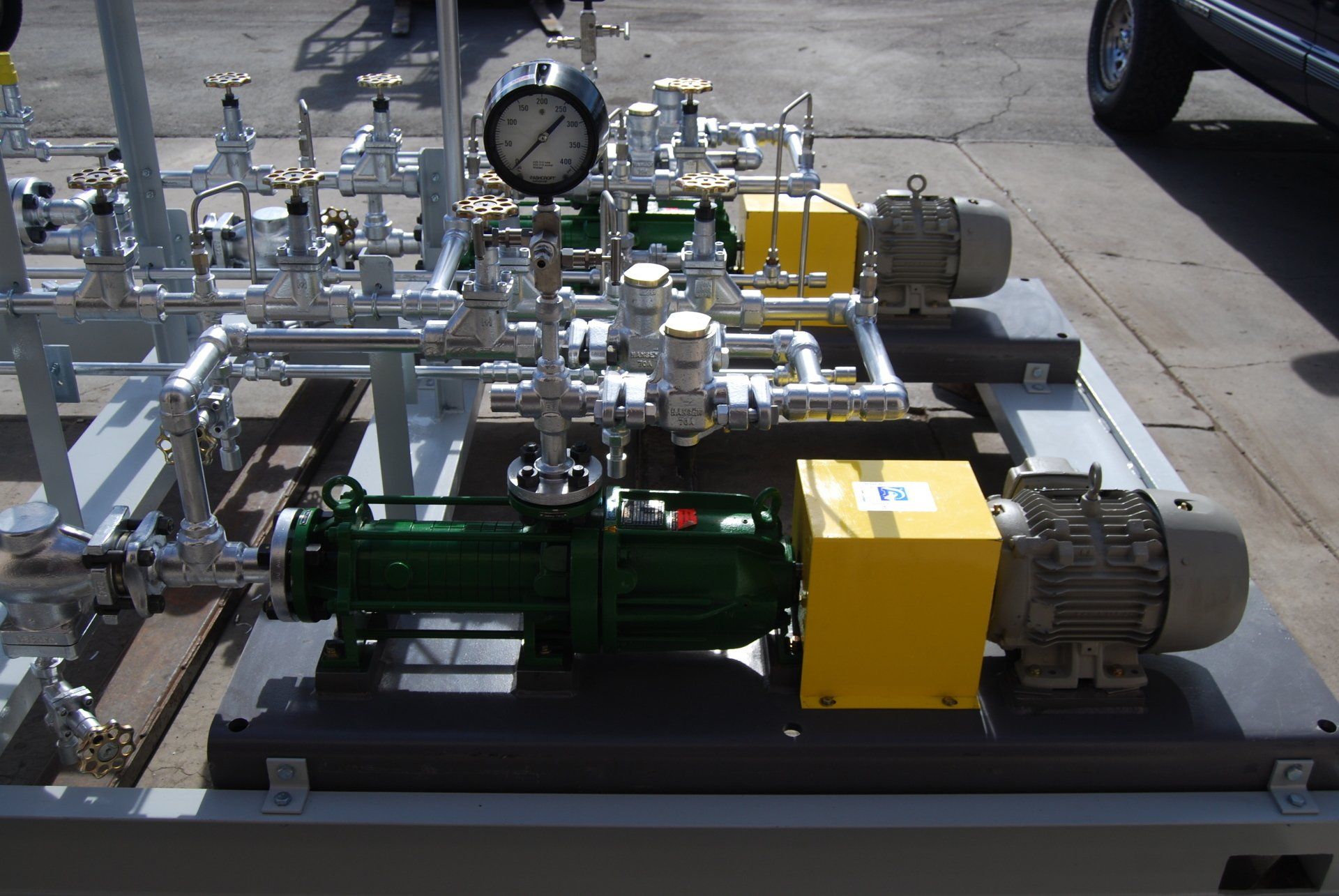

All the way from the precision custom machining, to ASME code pressure vessels to hold your process chemicals, to exotic alloy high pressure heat exchangers designed and built for your specific process to moving those process chemicals through ANSI B-31.3 Chemical Process Piping Code that requires the strictest of materials traceability and quality controls.

From grams per hour to tons per hour, EEServ has the Chemical Injection System to meet your process requirements.

INTEGRATED CHEMICAL INJECTION SYSTEMS

We can design the chemical process PFDs and P&IDs, develop the control philosophy, and write the control logic based on the P&IDs we develop. These can be developed into standalone programming for a wide variety of processors or assist with incorporation into your PLC or DCS. We then proceed to vessel design, component and instrument selection, and process layout, producing fabrication drawings and main bills of materials for purchasing.

PRECISION & FLEXIBILITY

When a project has been with EEServ from inception, customer changes and process improvements can be more easily incorporated at a lower cost anywhere along the production stream.

This is a great advantage for pilot work that may be in a state of flux.

For example, the ammonia injection system to the right was for condensate water treatment at a coal fired power plant. The site was having issues with water quality due to an aging injection system. EEServ reviewed the requirements, engineered a solution, designed the equipment, built the ASME vessels, piped the ANSI B-31.3 piping brought the skid assemblies together, developed control logic, programed the PLC, wired control panel and skid and, lastly, our field service group installed and commissioned the skids.

With EEServ's complete responsibility for the process, we become your single point of contact and, most importantly, we hold complete responsibility for the process and equipment. EEServ was able to make modifications to process control and equipment that allow for the exact conductivity the plant was seeking within the response times both at boiler start up and continuous operations.